In the current context of escalating global ‘plastic restrictions’ and the accelerated advancement of the circular economy, the disposal of plastic waste remains a complex challenge at the intersection of industrial production and environmental protection. On one hand, large accumulations of plastic waste such as single-use plastic packaging, agricultural films, and industrial scraps not only create ‘visual pollution’ but also pose ongoing threats to soil and water sources due to their non-biodegradable nature, continuously releasing microplastics; On the other hand, every tonne of recycled plastic can save 6 tonnes of crude oil. If efficiently processed, this not only generates significant revenue for businesses but also provides momentum for achieving the ‘dual carbon’ goals. Henan Haishihong Machinery Manufacturing Co., Ltd. has developed a plastic shredding and grinding production line, using technological innovation as the key to unlocking a new path for the resourceful utilisation of plastic waste.

First,the core role of plastic crushing and grinding production lines

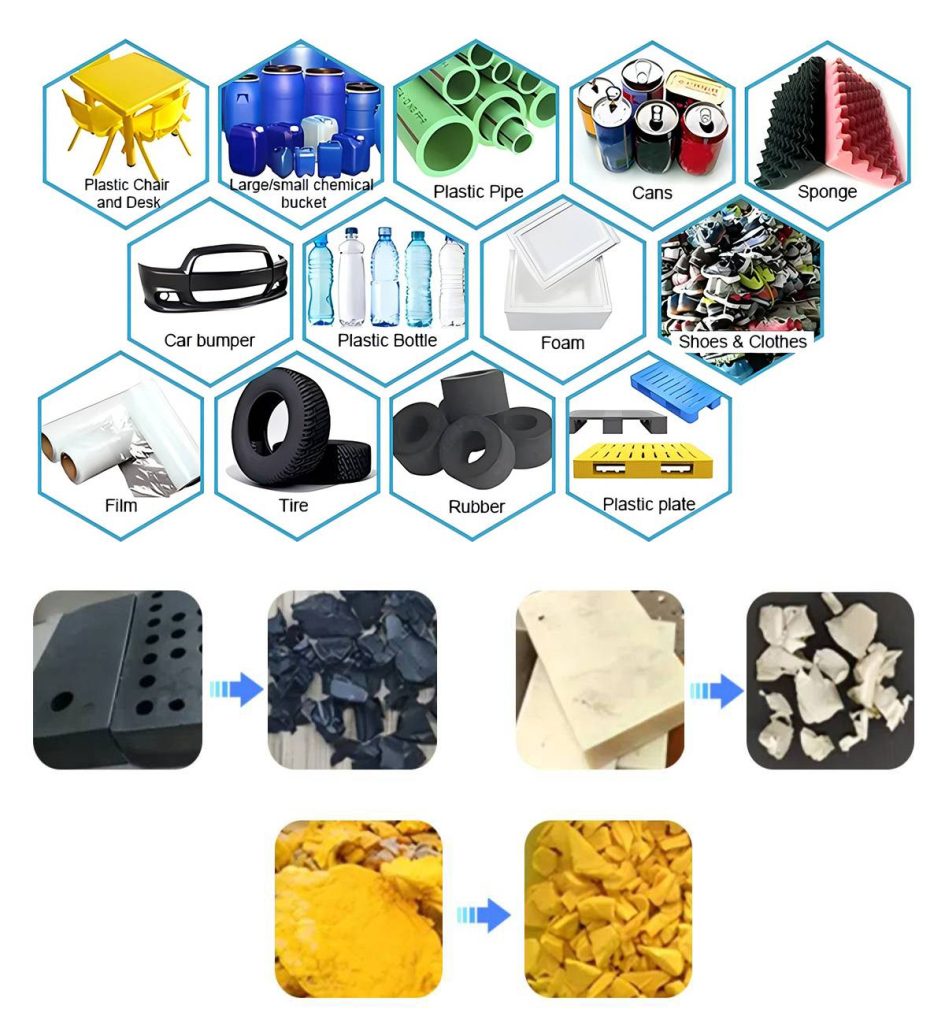

The plastic crushing and grinding production line is specifically designed to address the ‘processing pain points’ of various types of plastic waste, capable of precisely handling plastic waste of different shapes and materials. Whether it's everyday waste such as PET bottles and PP food containers, agricultural PE mulch film, industrial ABS scrap, or recycled plastic contaminated with sand and soil, this production line can transform them into uniform plastic pellets— — first undergoing pre-treatment to remove impurities, then undergoing multi-stage crushing and fine grinding, ultimately forming uniformly sized plastic pellets, laying the foundation for subsequent regeneration pelletisation, modification processing, and other stages.

Second,the Multi-dimensional Value of Plastic Shredding and Grinding Production Lines

The core value of plastic recycling lies in replacing virgin plastic and reducing crude oil consumption. This production line achieves this through precise shredding, transforming plastic waste that was previously difficult to utilise due to irregular shapes and excessive impurities into qualified recycled raw materials.If plastic waste is directly landfilled, it takes hundreds of years to degrade, and incineration releases toxic gases such as dioxins. The production line adopts a fully enclosed processing workflow, equipped with pulse dust collection and exhaust gas purification systems, achieving a dust collection rate of 99% during the crushing process, with harmful gas emissions far below national standards.

Third,typical application scenarios for plastic crushing and grinding production lines

With its adaptability to diverse plastics, this production line has been widely used in five major areas:Urban plastic recycling systems: processing waste plastics sorted and disposed of by residents to provide standardised raw materials for recycled material enterprises;Agricultural environmental protection: integrated processing of waste plastic film and greenhouse film through ‘crushing - washing - recycling’ to promote green agricultural development;Packaging and Printing Industry: Processing waste films and sheets generated during production, directly reusing them in production processes to reduce waste disposal;Electronics Recycling: Separating plastic casings from metal components in electronic devices, then specifically shredding the plastic components for use in manufacturing new appliance casings;Industrial Manufacturing Scenarios: Recycling plastic scrap from automobile and appliance production, re-moulding it after shredding to form an internal cycle of ‘production - recycling - re-production’.

Fourth,selection Guide for Plastic Shredding and Grinding Production Lines

When selecting a production line, companies should make precise decisions based on their specific processing needs:Identify plastic types: Soft plastics like PE and PP and hard plastics like ABS and PC have different requirements for shredding force, so appropriate blades and shredding chamber designs must be selected;Match processing capacity: Small recycling points can opt for compact production lines with an hourly output of 1-5 tonnes, while large-scale recycling enterprises require lines with capacities exceeding 10 tonnes;Focus on core configurations: Prioritise equipment equipped with intelligent sorting (to identify plastic materials), wear-resistant blades (to extend service life), and energy-efficient motors (to reduce operational costs);Emphasise customised services: Henan Haishihong Machinery can provide customised solutions from pre-processing to crushing based on the characteristics of the raw materials and site conditions of the enterprise, avoiding efficiency losses caused by ‘one-size-fits-all’ equipment.

The emergence of plastic crushing and grinding production lines is not only a technical response to ‘white pollution’ but also a key support for the implementation of a circular economy. It transforms waste plastic from an ‘environmental burden’ into an ‘economic resource,’ opening new pathways for businesses to reduce costs and improve efficiency while providing practical solutions for societal sustainable development. As technology continues to evolve, Henan Haishihong Machinery will remain innovation-driven, ensuring that every piece of waste plastic is revalued, and together we build a green future.