Case Study: How a European Recycling Firm Tripled Waste Foam Processing Capacity with Advanced Shredding Equipment

In the small industrial town of Venlo, the Netherlands, EcoCycle Recycling—a mid-sized waste management company—was once trapped in a dilemma: surging volumes of waste foam from local packaging factories and e-commerce warehouses were piling up faster than the firm could process, leading to delayed orders and rising storage costs. Today, just six months after adopting a dual-shaft waste foam shredder from a leading Chinese manufacturer, the company has tripled its daily processing capacity, cut operational costs by 28%, and turned a once-burdensome waste stream into a profitable recycled resource.

Before the upgrade, EcoCycle relied on two single-shaft shredders purchased five years ago. These machines struggled with the low density and fluffy texture of EPS (expandable polystyrene) and EPE (ethylene-vinyl acetate) foam—often clogging mid-operation, requiring frequent manual cleaning, and producing unevenly shredded pieces. “We could only process 8 to 10 tons of waste foam per day,” said Jan Visser, EcoCycle’s Operations Manager. “With 15+ tons arriving daily, we had to rent extra storage space, which cost us €3,000 monthly. Worse, the inconsistent shred size made it hard to sell to downstream granulation plants—our main buyers kept complaining about quality.”

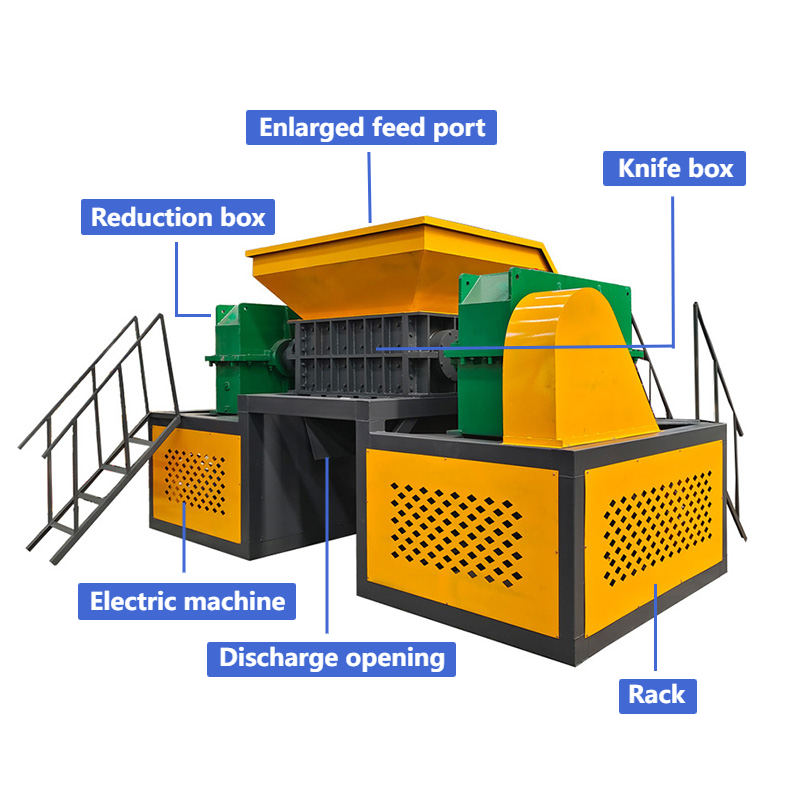

Seeking a solution, EcoCycle’s team researched global suppliers and ultimately chose a dual-shaft waste foam shredder designed for high-volume, low-maintenance operation. Key features of the equipment included anti-clogging dual rotors with serrated blades (optimized for cutting through light, bulky foam), an integrated dust collection system (to address foam dust pollution), and an intelligent control panel that adjusts speed based on foam thickness—reducing jams by 90%.

The results were immediate. Within the first month, EcoCycle’s daily processing capacity jumped to 25 tons, eliminating the need for extra storage. The uniformly shredded foam (10-20mm pieces) met the strict standards of its granulation partners, leading to a 15% higher selling price per ton of recycled foam. “Our buyers now prioritize us because we can deliver consistent quality in large batches,” Visser noted. “We’ve even signed two new contracts with German packaging companies that needed reliable foam recycling partners.”

Beyond capacity and revenue gains, the shredder’s energy efficiency also made a significant impact. Equipped with a 15kW energy-saving motor, the machine uses 32% less electricity than the old single-shaft models—translating to €1,800 in monthly energy savings. Additionally, the durable alloy blades require replacement only once every 12 months, compared to every 3 months for the old equipment, cutting maintenance costs by 67%.

For EcoCycle, the investment in advanced waste foam shredding technology has been a game-changer. “We went from struggling to keep up with waste to leading the local recycling market,” Visser said. “This equipment isn’t just a machine—it’s helped us turn ‘white pollution’ into a sustainable business driver. We’re now planning to add a second shredder next year to handle even more foam waste from neighboring countries.”

This case underscores how purpose-built waste foam shredders are empowering recycling enterprises worldwide to overcome operational challenges, boost profitability, and contribute to a circular economy—proving that with the right technology, waste can become a valuable resource.